Cast iron pipes have been a staple in home plumbing systems for decades, prized for their durability and longevity. However, even the sturdiest materials are not immune to damage over time. Understanding what causes cast iron pipe to crack is crucial for homeowners, especially those in older homes, to maintain their plumbing systems effectively. This knowledge will help you identify potential issues early and take the necessary steps to preserve the integrity of your plumbing system.

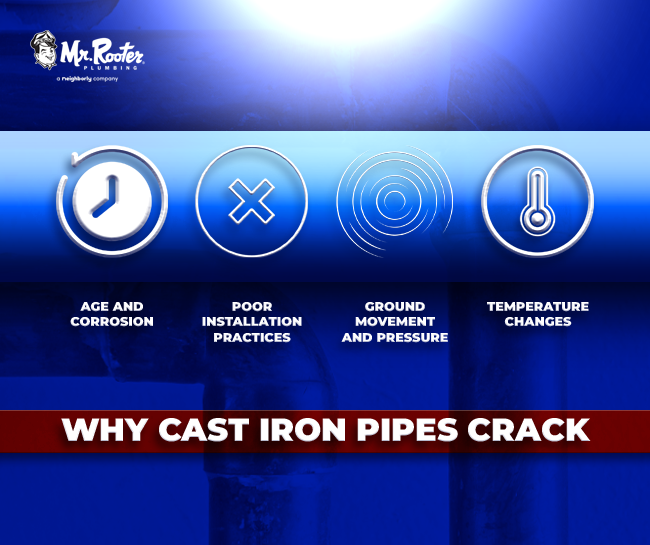

Why Cast Iron Pipes Crack

Understanding why cast iron pipes crack is crucial for maintaining a home’s plumbing integrity. Various factors contribute to this common issue, each playing a significant role in the longevity and reliability of these pipes.

Age and Corrosion

The lifespan of cast iron pipes is typically lauded, often lasting upwards of 50 to 100 years. Yet, as these pipes age, they become susceptible to corrosion, a natural process exacerbated by the presence of moisture and certain chemicals in the soil. This corrosion eats away at the pipe’s interior, gradually weakening it until cracks appear. Regular inspections can help identify corrosion early, potentially extending the pipe’s service life.

Poor Installation Practices

Proper installation is key to the longevity of cast iron pipes. Unfortunately, improper handling, alignment issues, or inadequate support during installation can introduce stresses that may not be evident until years later. These stresses can lead to micro-fractures that eventually widen, causing significant damage. Ensuring installation by experienced professionals is a preventative measure not to be overlooked.

Ground Movement and Pressure

External pressures, such as ground movement from soil settling or heavy traffic vibrations, can also stress cast iron pipes. Over time, these pressures can lead to cracks, especially where the pipes are most vulnerable. Homeowners should be mindful of changes in their property’s landscape and consider them when assessing their plumbing’s health.

Temperature Changes

Seasonal temperature fluctuations can cause cast iron pipes to expand and contract, a process that can lead to cracks over time. This is particularly true in regions with extreme weather changes, highlighting the importance of insulation and other protective measures in safeguarding plumbing infrastructure.

💡 By understanding these factors, homeowners can take proactive measures to prevent or mitigate the risk of cast iron pipe cracking, such as regular inspections, proper installation, and protective measures against external pressures and temperature changes.

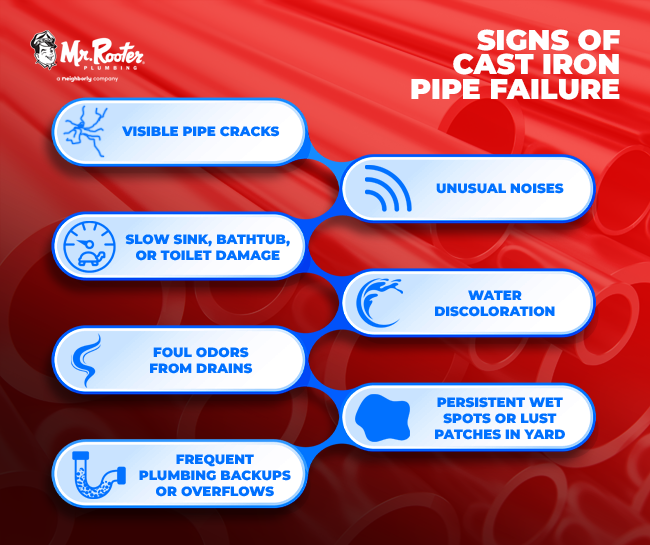

Signs of Cast Iron Pipe Failure

Detecting early signs of cast iron pipe failure is key to preventing extensive damage and costly repairs. The following checklist can help homeowners identify potential issues before they escalate, ensuring the longevity and efficiency of their plumbing systems.

- Visible cracks or leaks in the pipe

- Unusual noises, such as creaking or banging, coming from the pipes

- Slow drainage in sinks, bathtubs, or toilets

- Water discoloration, indicating rust or sediment inside the pipe

- Foul odors emanating from drains, suggesting blockages or decay within the pipe

- Persistent wet spots or unexplained lush patches in the yard, which could indicate an underground leak

- Frequent plumbing backups or overflows, pointing to compromised pipe integrity

💡Early detection of cast iron pipe issues is vital to prevent costly repairs. Spotting signs like cracks, leaks, unusual noises, slow drainage, water discoloration, foul odors, wet spots, or backups enables proactive maintenance. Understanding causes like corrosion and age aids in prevention and decision-making for maintenance and replacement.

Maintenance and Prevention

Proactive maintenance and prevention are your best defenses against the costly and inconvenient consequences of cast iron pipe failure. By adhering to the following guidelines, homeowners can significantly extend the life of their plumbing systems and avoid common pitfalls associated with pipe deterioration.

- Regularly inspect pipes for signs of rust, corrosion, or damage.

- Avoid pouring harsh chemicals, oils, or grease down the drains, which can accelerate corrosion.

- Use water softeners if your water supply is hard, as mineral buildup can also affect pipe integrity.

- Ensure proper insulation of pipes to mitigate the effects of temperature fluctuations.

- Schedule annual professional inspections to identify and address potential issues early.

- Keep trees and large plants away from pipelines to prevent root intrusion and physical damage.

- Implement a regular cleaning schedule to prevent blockages that can increase pressure and stress on pipes.

When to Replace Cast Iron Pipes

Deciding to repair or replace damaged cast iron pipes depends on the extent of the damage, the age of the plumbing, and the cost implications. In cases where repairs are frequent or the system is nearing the end of its expected lifespan, replacement with more modern materials may be the most economical and practical solution.

Understanding what causes cast iron pipe to crack is essential for you to maintain your plumbing system effectively. By recognizing early signs of damage, conducting regular maintenance, and making informed decisions about repair or replacement, you can ensure the longevity and reliability of your home’s plumbing system.