Cast iron pipes have been essential components of plumbing systems for generations, offering durability and reliability. For homeowners and commercial space owners alike, understanding the different types of cast iron pipe is crucial for making well-informed decisions about their plumbing needs. In this guide, you’ll explore the various types of cast iron pipe and their specific applications, ensuring you choose the right one for your project.

History of Cast Iron Pipes

Cast iron pipes have a rich history tracing back to ancient civilizations. The Romans were among the first to utilize them for their aqueducts, demonstrating the material’s strength and longevity. Over time, cast iron pipes evolved, becoming a staple in modern plumbing systems. However, with advancements in technology and material sciences, alternatives began to emerge, leading to a shift away from traditional cast iron.

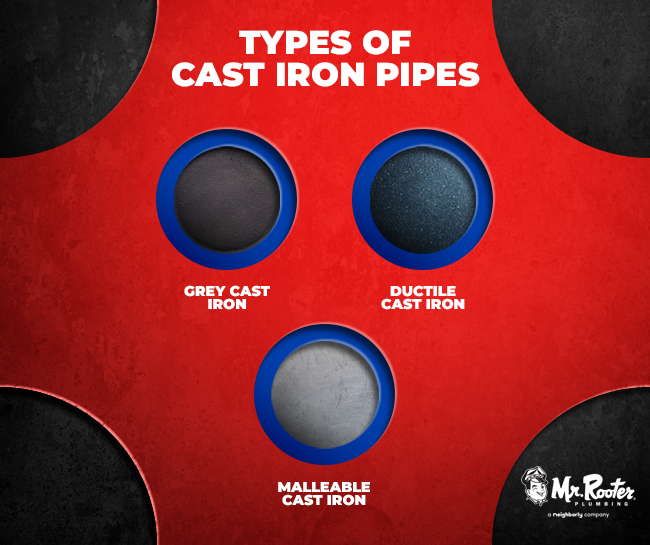

Types of Cast Iron Pipes

- Grey Cast Iron:

This type of cast iron is the most common in plumbing applications due to its affordability and ease of production. Grey cast iron pipes are renowned for their resistance to external pressures, making them suitable for underground installations.

- Ductile Cast Iron:

Unlike grey cast iron, ductile cast iron offers enhanced flexibility and strength. Its ductility makes it resistant to cracking and snapping under pressure, making it ideal for areas prone to ground movement or seismic activity.

- Malleable Cast Iron:

While less common in plumbing, malleable cast iron possesses exceptional ductility, allowing it to be shaped and molded with ease. It finds its niche in specialized plumbing applications where flexibility and adaptability are paramount.

💡 Each type has its own advantages, so choosing the right one depends on the specific needs of your plumbing system.

Why Cast Iron Pipes Are Not Used Anymore

Despite their historical significance, cast iron pipes have faced challenges in modern plumbing systems. Issues such as corrosion and limited lifespan have prompted a transition towards more sustainable and durable materials like PVC and HDPE. Additionally, the environmental impact of cast iron production has spurred efforts to explore eco-friendly alternatives.

The Most Widely Used Type of Cast Iron Pipe

Grey cast iron remains the most widely used type of cast iron pipe in both residential and commercial settings. Its balance of cost-effectiveness and reliability makes it a preferred choice for many plumbing projects. However, it’s essential to evaluate specific requirements and consider alternatives based on factors such as longevity and environmental impact.

Considerations for Choosing Cast Iron Pipes

When selecting cast iron pipes for your plumbing project, several key factors should be taken into account. Here are some considerations to keep in mind:

- Cost: Evaluate the upfront cost of cast iron pipes against their long-term durability and maintenance expenses.

- Durability: Consider the robustness of cast iron pipes and their ability to withstand external pressures and environmental factors.

- Application Requirements: Assess the specific needs of your plumbing project and ensure that cast iron pipes meet the necessary specifications.

- Longevity: Examine the expected lifespan of cast iron pipes and compare it with alternative materials to determine the most cost-effective solution.

- Maintenance: Factor in the maintenance requirements of cast iron pipes, including routine inspections and potential repairs.

- Compatibility: Ensure that cast iron pipes are compatible with existing plumbing systems and meet regulatory standards for your region.

💡By carefully considering these factors, you can make an informed decision about whether cast iron pipes are the right choice for your plumbing needs.

Understanding the different types of cast iron pipes empowers homeowners and commercial space owners to make informed decisions about their plumbing systems. While traditional cast iron has seen a decline in usage, it still holds relevance in certain applications. Consulting with a professional plumber and evaluating specific needs will ensure the optimal selection of plumbing materials for any project.