Struggling with cast iron pipe issues in your home? You’re not alone. These pipes, while robust, can develop problems as they age. This guide is your essential resource for navigating the complexities of cast iron pipe repairs. Our comprehensive instructions on how to repair cast iron pipe will guide you through each step, empowering you to extend the life and efficiency of your plumbing system with expert tips and practical advice.

Understanding Cast Iron Pipes

Cast iron pipes are known for their robustness and resistance to corrosion. They are typically used in sewer systems and older residential plumbing. Their thick walls provide excellent sound insulation and reduce the likelihood of pipe bursts.

Common Issues and Their Causes:

Cast iron pipes are known for their longevity, but they are not impervious to certain issues over time. Understanding these common problems and their causes is crucial for effective maintenance and repair. Here’s a breakdown of the typical challenges you might encounter:

- Corrosion and Rusting: Prolonged exposure to moisture and certain chemicals can lead to rust and corrosion, weakening the pipe structure.

- Cracking: Temperature changes, ground movement, or internal pressure fluctuations can cause cracks in cast iron pipes.

- Joint Failures: The joints in cast iron piping can fail due to age, improper installation, or shifting soil.

- Scale Build-up: Over time, mineral deposits can accumulate inside the pipes, leading to blockages and reduced water flow.

- Tree Root Intrusion: Roots from nearby vegetation can infiltrate joints or cracks in the pipes, causing blockages or further damage.

- Bellied Pipes: Sections of the pipe can sag due to ground conditions, leading to water pooling and sediment build-up.

💡By identifying these issues early, homeowners can take proactive steps to repair and maintain their cast iron pipes, ensuring a functional and reliable plumbing system.

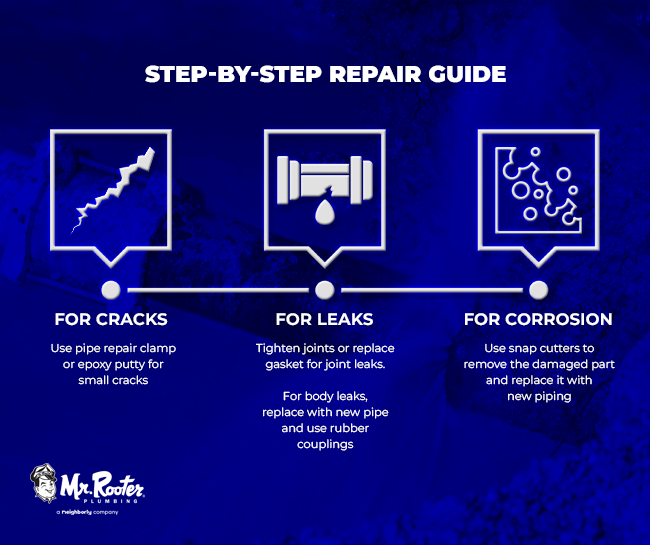

Step-by-Step Repair Guide

Begin with a thorough inspection. Look for visible signs of damage like cracks, leaks, or rust. Use inspection cameras for inaccessible areas. Pay attention to joints and connections, as these are common failure points.

- For Cracks: Clean the area around the crack. Apply a pipe repair clamp or use epoxy putty for small cracks, ensuring the area is dry before application.

- For Leaks: If the leak is at a joint, tighten the joint or replace the gasket. For leaks in the pipe body, cut out the damaged section and replace it with a new pipe, using rubber couplings for a secure fit.

- For Corrosion: Extensive corrosion might necessitate replacing large sections of the pipe. Use snap cutters to remove the damaged part and replace it with new piping, ensuring all connections are secure and leak-free.

When to Call Professional Help

Some scenarios, like extensive corrosion, large cracks, or inaccessible damage, demand professional expertise. If you’re unsure about any aspect of the repair process, it’s prudent to consult a professional.

Benefits of Hiring a Professional for Complex Repairs

Opting for a professional plumber for complex cast iron pipe repairs brings several key advantages:

- Expertise: Professionals possess the necessary skills and experience for accurate and efficient repairs.

- Advanced Equipment: They have access to specialized tools that are crucial for complex jobs.

- Time-Saving: Professional intervention often means quicker resolution, minimizing disruption.

- Longevity: Repairs done by experts are generally more durable, reducing future issues.

- Safety: Professionals understand how to safely handle plumbing risks.

- Code Compliance: They ensure repairs meet local building codes and regulations.

- Warranty: Many professionals offer guarantees on their work, providing added peace of mind.

- Stress Reduction: Entrusting complex repairs to experts alleviates the stress and uncertainty for homeowners.

Preventive Maintenance

Regular inspection and cleaning are vital. Look for signs of corrosion or damage during routine checks and clean the pipes to prevent blockages. Avoid chemical drain cleaners, as they can accelerate corrosion.

Signs to Watch for Potential Problems

Being vigilant about the condition of your cast iron pipes can help you address issues before they escalate. Here are key signs to watch for, indicating potential problems:

- Water Discoloration: Rust or debris in your water can signal pipe corrosion.

- Unusual Noises: Banging or gurgling sounds may indicate pipe blockages or structural issues.

- Slow Drains: Consistently slow draining can be a sign of blockages or pipe damage.

- Foul Odors: Persistent sewer-like smells could point to cracks or leaks in the pipes.

- Visible Rust: Any visible rust on the outside of pipes suggests internal corrosion.

- Leaks: Damp spots on walls or floors near plumbing lines can indicate leaks.

- Water Pressure Fluctuations: Sudden changes in water pressure might be caused by pipe deterioration.

💡 Regularly checking for these signs can help you catch and address pipe issues early, potentially saving you from more extensive and costly repairs in the future.

This guide offers a detailed approach to repairing and maintaining cast iron pipes. By understanding the intricacies of how to repair cast iron pipe and following our step-by-step instructions, you can ensure their longevity and functionality. Whether you tackle repairs yourself or seek professional assistance, regular maintenance is key to a healthy plumbing system.